Driver: TF029B-1001-D

- ●To make a purchase, contact Distributors, or use e-commerce below.

SALES CHANNEL ;Check our Distributors.- SALES CHANNELClick here to check our Distributors.

Dedicated to the Micro Blower TF029 series

- The drivers enable users to vary the speed of the motor by adjusting the control voltage of the external input.

- Contents of the kit are Driver board and Harness.

- Wire Harness: for Driver-Power connection

STANDARD SPECIFICATIONS

- Unless otherwise specified, the environmental conditions are 23°C±5°C, normal humidity, and atmospheric pressure range 90 to 106kPa

| No. | Item | Item | |||

|---|---|---|---|---|---|

| 1 | Configuration | Drivers(Dedicated to the Micro Blower TF029 series) | |||

| 2 | Rotational Speed | 36,000 r/min(reference value) at 2.0kPa, 100L/min | |||

| 3 | Power Consumption | 14.9W max. at 2.0kPa, 100L/min | |||

| 4 | Rated Voltage | DC 24 V±10% | |||

| 5 | Max. Input Current | 2.0 A max.(DC) (Excluding inrush current) | |||

| 6 | Readiness time | 5sec max.From power on to motor start | |||

| 7 | Running Current | 0.62 A max. at 2.0kPa, 100L/min | |||

| 8 | Weight | 40 g max. | |||

| 9 | Operating Temperature | -10~ 50 °C | |||

| 10 | Operating Humidity Range | 10~ 90 %RH (No condensation) | |||

| 11 | Storage Temperature | -20~ 60 °C | |||

| 12 | Storage Humidity Range | 10~ 90 %RH (No condensation) | |||

| 13 | Resistance to Vibration | To meet the Spec after the following test | Non-operating | ||

| Kind of Vibration | Frequency Rang | ||||

| Frequency Range | 10 ~ 22Hz amplitude 1mm | ||||

| 22 ~ 50Hz, 19.6m/s2 (2G acceleration) | |||||

| Sweep | to-and-fro, approx. 5min. | ||||

| Test Time | X, Y, Z directions, 60min. each | ||||

| 14 | Resistance to Shock | To meet the Spec after the following test | Non-operating | ||

| Acceleration | 294m/s2(30G) | ||||

| Pulse Width | 6ms | ||||

| Shock Waven | Semi-sinusoidal wave | ||||

| Number of Shock | X, Y, Z, directions, once per each direction | ||||

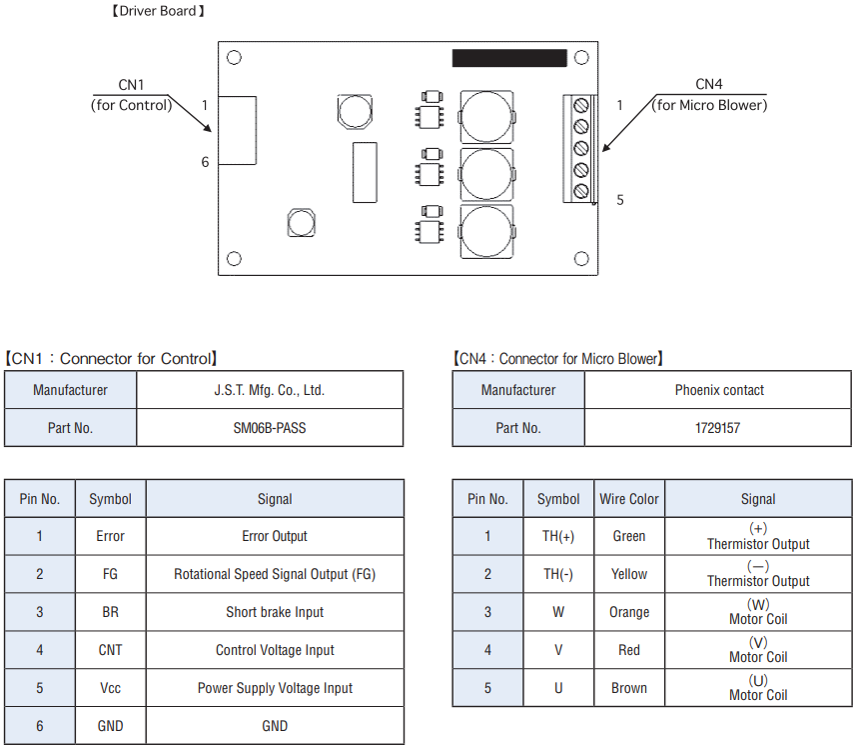

INTERFACE

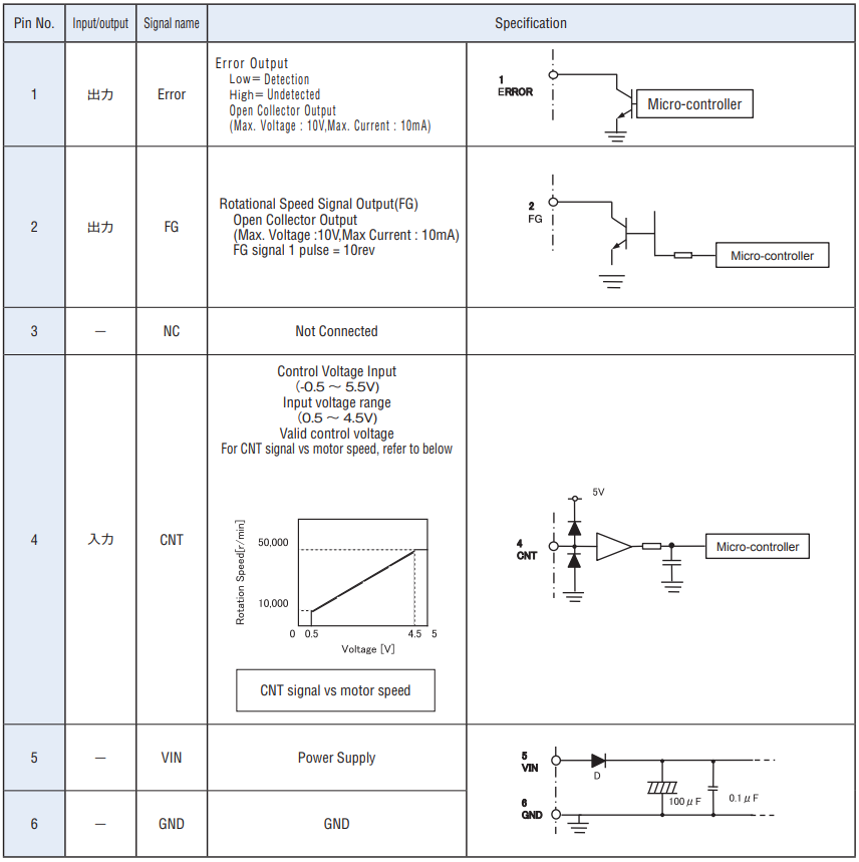

CN1(CONNECTOR FOR CONTROL) SPECIFICATIONS

POWER SUPPLY,CONTROLLER VOLTAGE INPUT

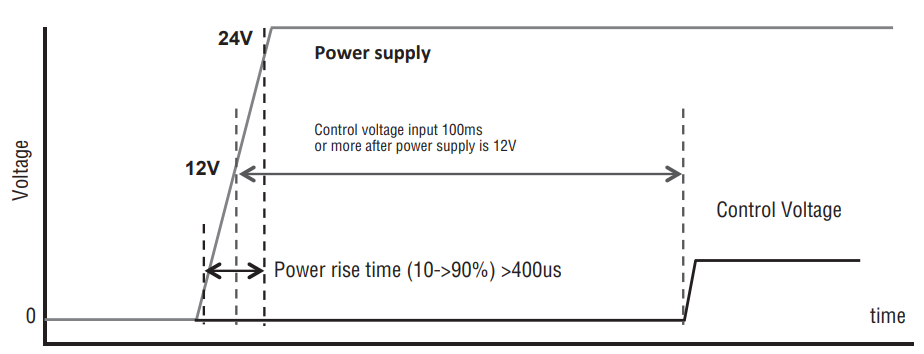

※To avoid high in rush current and protect driver, follow below chart at power up and CNT signal input sequence

- ① Keep power rise time(10 → 90%) is more than 400us. If high rate power is applied, in rush current will be so huge.

- ② Wait more than 100ms after power exceeds 12V to apply CNT signal.

PROTECTIVE FUNCTIONS

| Protective Functions | Description |

|---|---|

| Over current | If over voltage detected at power line, Blower will be stopped. Recover: Check and correct supply voltage. |

| Over current | When power line current exceeds 3A, fuse will be opened and cut off power. Recover: Contact with us. |

| High temperature | When high Turbo Fan internal temperature, outputs error signal and turn it off. If error is detected, LED will blink at 1Hz Recover: Wait until it's cooled down and try again. (If not solved, contact with us.) |

| Over speed | When motor speed exceeds limit, outputs error signal and turn it off. If error is detected, LED will blink at 1Hz Recover: Reduce CNT signal voltage and try again.(If not solved, contact with us.) |

| Over current at motor coil | When motor coil current exceeds limit, outputs error signal and turn it off. Recover: Check motor operation condition. |

| Abnormal voltage of supplied power | When power supply voltage exceeds limit, outputs error signal and turn it off. If error is detected, LED will blink at 1Hz Recover: Check power supply voltage and try again |

| Abnormal operation | When any failure is detected on driver, outputs error signal and turn it off. If error is detected, LED will blink at 4Hz Recover: Check power supply voltage and try again.(If not solved, contact with us) |

- Normal operation : Green LED is ON. (Red is OFF.)

- Abnormal condition : Red LED is blinking. (Green is turned off.)

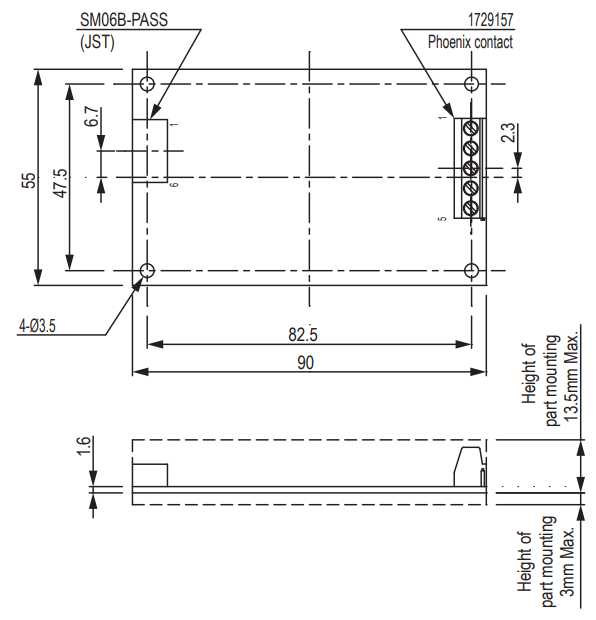

OUTLINE DIMENSIONS

|

|---|

Documents

- ●The above contents and descriptions are subject to change without notice.