6-Axis Force Sensors Special Feature

6-Axis Force Sensors Special Feature

- Chapter 1 NIDEC COMPONENTS' Innovative Technology:

- Shaping the Future of Precision Control with 6-Axis Force Sensors

The industrial sector is currently facing pressing challenges, including soaring labor costs and a severe labor shortage. This situation is significantly accelerating the adoption of robot technology and expanding the market across diverse fields such as manufacturing, logistics, medical care, and nursing care. In particular, the dramatic advancements in Artificial Intelligence (AI) and Machine Learning are promoting the development of next-generation robots capable of performing advanced and delicate tasks equal to or surpassing human capabilities. Achieving this requires highly sensitive and precise sensor technology.

Development Background: Maximizing Cobot Performance

The Core of Precision Measurement: Technical Advantages of the 6-Axis Force Sensor

Technical Advantages

-

Pushing/Pulling

Pushing/Pulling -

Twisting

Twisting -

Tilting

Tilting

Applications and Technical Advantages Realized by the 6-Axis Force Sensor

What a 6-axis force sensor can achieve

- Innovation in Precision Assembly and Processing

Tasks that traditionally relied on the tactile sensation/sense of skilled workers, such as connector insertion, polishing, and precision fitting, are automated by robots with extremely high accuracy. This leads to a dramatic improvement in production efficiency and quality.

- Optimization of Logistics and Inspection Processes

When mounted on a robot hand, it can differentiate not only the external appearance of packages but also detect mass differences, reliably preventing insufficient counts or erroneous transportation.

- Contribution to Medical and Nursing Care Fields

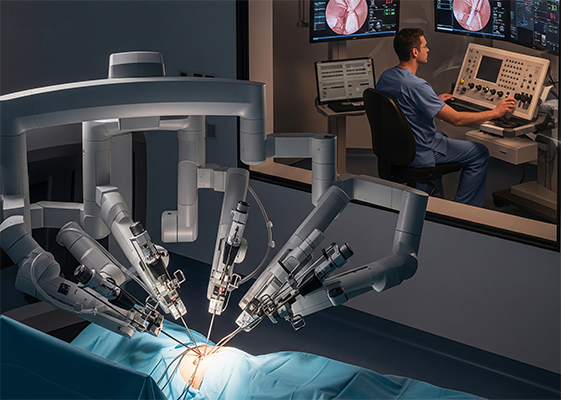

In surgical assistance robots, it provides real-time control of force feedback between the primary side (operator) and the secondary side (working device), faithfully reproducing the surgeon's delicate tactile sensations. Furthermore, it optimizes the force applied by rehabilitation robots and nursing care support robots when touching the human body, enabling safe and gentle assistance.

- Advanced Autonomous Control of Humanoid Robots

When installed in the soles of the feet or joints of bipedal humanoid robots, it precisely detects ground reaction forces and loads applied to the body. This enables advanced autonomous control such as stable walking on uneven terrain, balance maintenance, and fall avoidance, accelerating research and development towards practical application.

- Chapter 2 Key Features:

- Reliable Value Provided by NIDEC COMPONENTS

Our 6-axis force sensor meets diverse customer needs through its outstanding characteristics.

- High Moment Ratio

Suppresses the influence of inertial moments during sudden stops and accelerations of robots, enabling ample motion that can withstand unexpected loads.

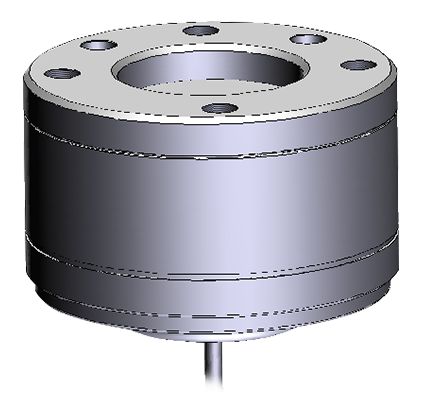

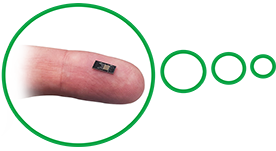

- Small Diameter and Thin Design

The compact φ 63 mm housing allows direct mounting on robot arms, contributing to overall system space-saving and increased design freedom.

- High Impact Resistance (Equipped with Dedicated Stopper Mechanism)

Our unique metal thin-film deposition technology and dedicated stopper mechanism physically prevent damage to the sensor body from excessive external forces or impacts, contributing to long-term reliability and reduced operational costs.

- Excellent Environmental Resistance

In addition to employing highly sensitive and low-temperature coefficient strain gauges, its IP65-equivalent dust and water resistance ensures consistent, high-precision measurement even in environments with drastic temperature changes or harsh conditions involving dust and water.

- High-Speed Sampling

High responsiveness in capturing instantaneous force changes enables real-time precision control of robots, achieving smoother and more delicate movements.

- Superior Cost Performance and High Quality

Our vertically integrated production system, which encompasses everything from sensor element manufacturing to assembly and calibration at our own factory, ensures thorough quality control and significant cost efficiency.

Through this 6-axis force sensor, strongly supports our customers' technological innovations and contributes to the realization of future.

6-axis Force Sensor Demo

We visualized the strain and stress acting on the sensor. Please watch the high sensitivity and precision of our 6-axis force sensor.

Technical Specifications

| Model Name | FS063 | FS063 | |||

|---|---|---|---|---|---|

| Dimension | Outer Diameter | φ 63 mm | |||

| Thickness | 38 mm | ||||

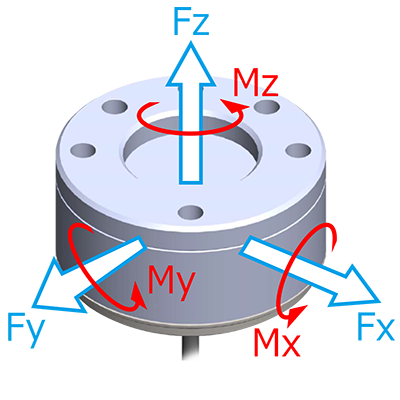

| Rated Load | Fx, Fy, Fz | ± 300 N | |||

| Mx, My, Mz | ± 30 Nm | ||||

| Overload Capacity | 400 % F.S. | ||||

| Linearity | ± 3 % F.S. | ||||

| Hysteresis | 3 % F.S. | ||||

| Crosstalk | ± 5 % F.S. | ||||

| Weight | 490 g | ||||

| Protection Class | IP65-equivalent | ||||

| Communication Interface | RS-485 | ||||

|

|||||

This specification applies to our standard products.

- Chapter 3

- 6-Axis Force Sensor: Expanding Application

Our 6-axis force sensor provides innovative solutions across a wide range of fields thanks to its high-precision force and moment detection capabilities. Here are some of the most notable applications:

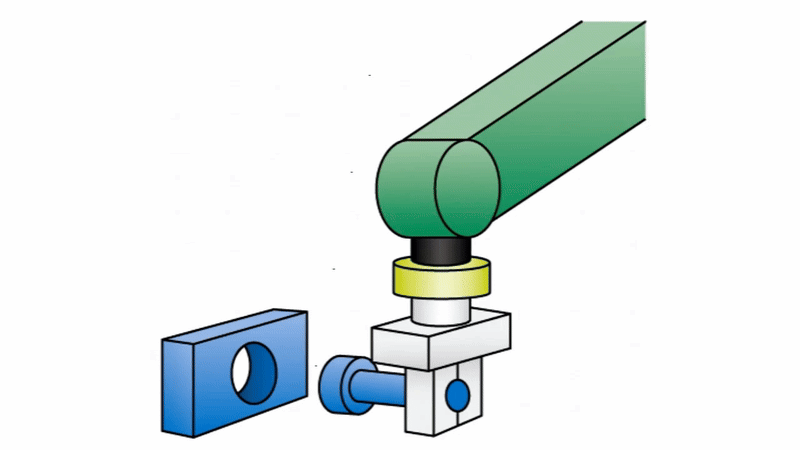

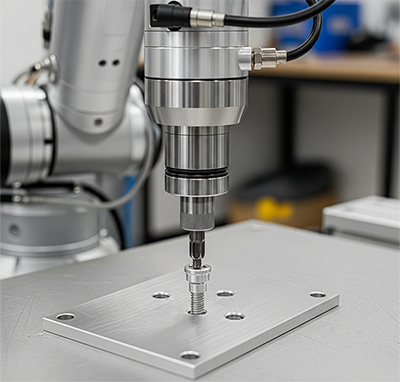

1. Precision Assembly and Processing by Robots

Precision Fitting

Detects slight misalignments or resistance in parts, automatically optimizing connector insertion and precision component assembly.

Polishing and Deburring

Real-time sensing of surface shape and hardness changes of workpieces enables uniform polishing and efficient deburring.

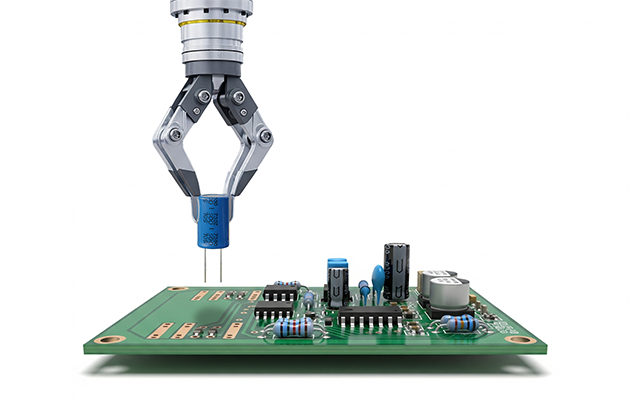

Handling Delicate Components

Gently grasps and transports soft or fragile components without damage.

Screwing and Torque Management

Tightens screws with appropriate torque, preventing overtightening or loosening.

2. Advanced Logistics and Inspection

Adaptation to Various Packaging

Detects changes in the center of gravity and shape of palletized loads, allowing safe and efficient loading and unloading of even unstable items.

Quantity and Quality Inspection

Detects subtle differences in product weight within packages and packaging distortions, preventing shortfalls or mis-shipment of defective products.

3. Applications in Medical and Nursing Care

Surgical Assistance Robots

Supports safer and more precise surgeries by real-time control of force interaction between the operator (primary) and the working device (secondary) (primary/secondary control), faithfully reproducing the surgeon's delicate sensations.

Rehabilitation Robots

Supports exercise with optimal force adjustment according to the patient's condition, promoting effective rehabilitation while preventing excessive load.

Nursing Care Support Robots

Adjusts the force applied when touching a person's body, enabling safe and gentle assistance.

4. Research and Development & Other Special Applications

Humanoid Robot Balance Control

Utilized for advanced balance control in bipedal robots, such as stabilizing posture by detecting forces on the soles of their feet and walking without falling on uneven terrain.

Force Feedback Devices

Provides a more realistic sense of operation and immersion in remote control and simulations by transmitting reaction forces from objects to the operator.

Material Property Evaluation

Accurately measures minute forces and deformations, useful for evaluating the strength and properties of new materials.

Contact Us